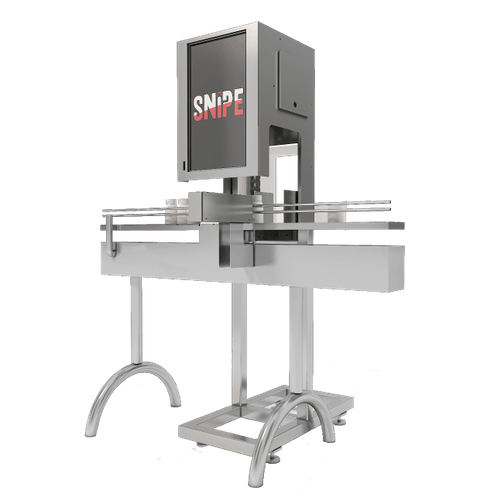

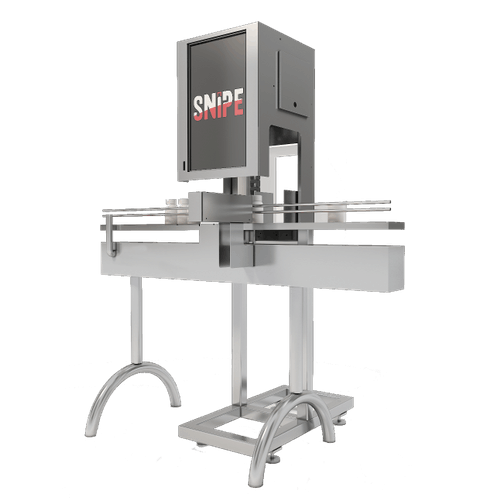

Snipe is an online induction seal inspection system for retrofit onto existing bottle packaging lines.

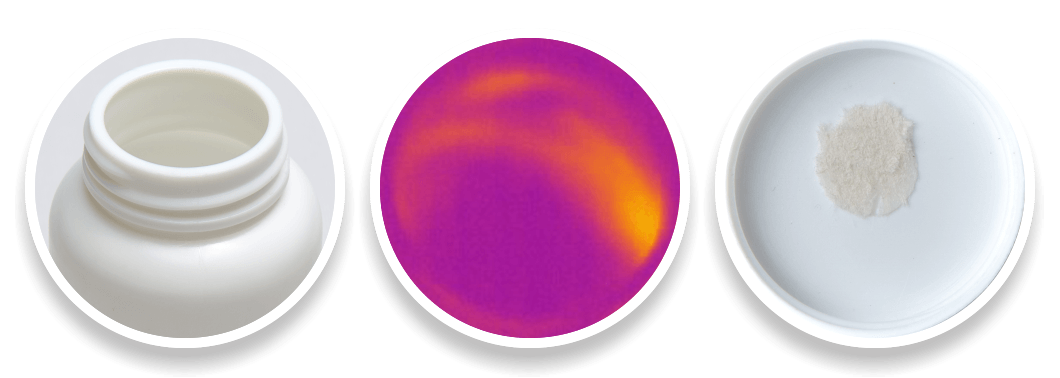

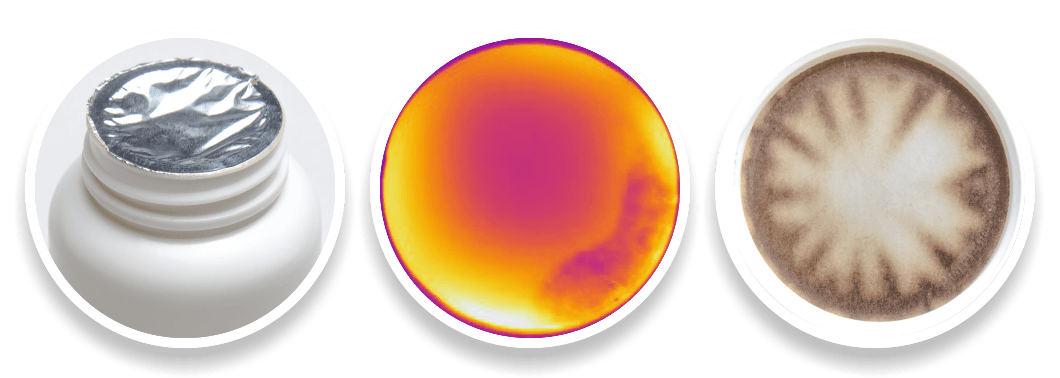

Poor induction seal quality remains a serious concern in the pharmaceutical industry. Sub standard seals can lead to contamination and reduced potency when exposed to harsh environments.

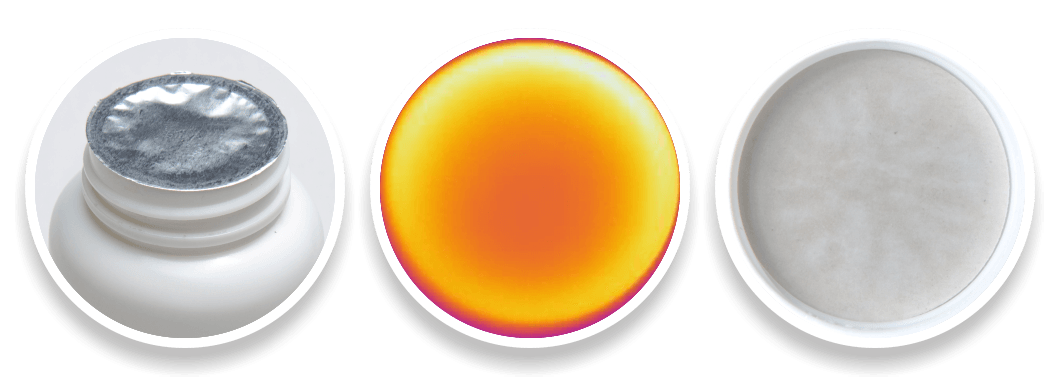

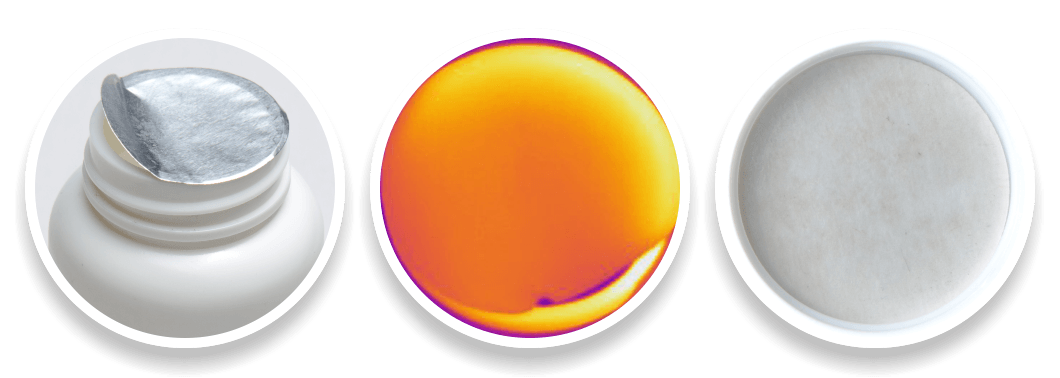

Using the latest in high resolution thermal technology, Snipe accurately detects any areas of potential leakage on a seal, verifying the integrity of the bottle and rejecting any defective products via a pneumatic rejection mechanism.

Configurable for bottle variants of any height, the system has also been designed with a high level of versatility.