SUMMARY

Discus is a automated vision solution that accurately detects the angular position of a weld bead on a wheel rim in under 40ms.

During the manufacture of wheel rims, the location of the weld bead is used to select the position of the valve hole. The placement of this hole must be extremely accurate in order to avoid subsequent issues in both production and testing.

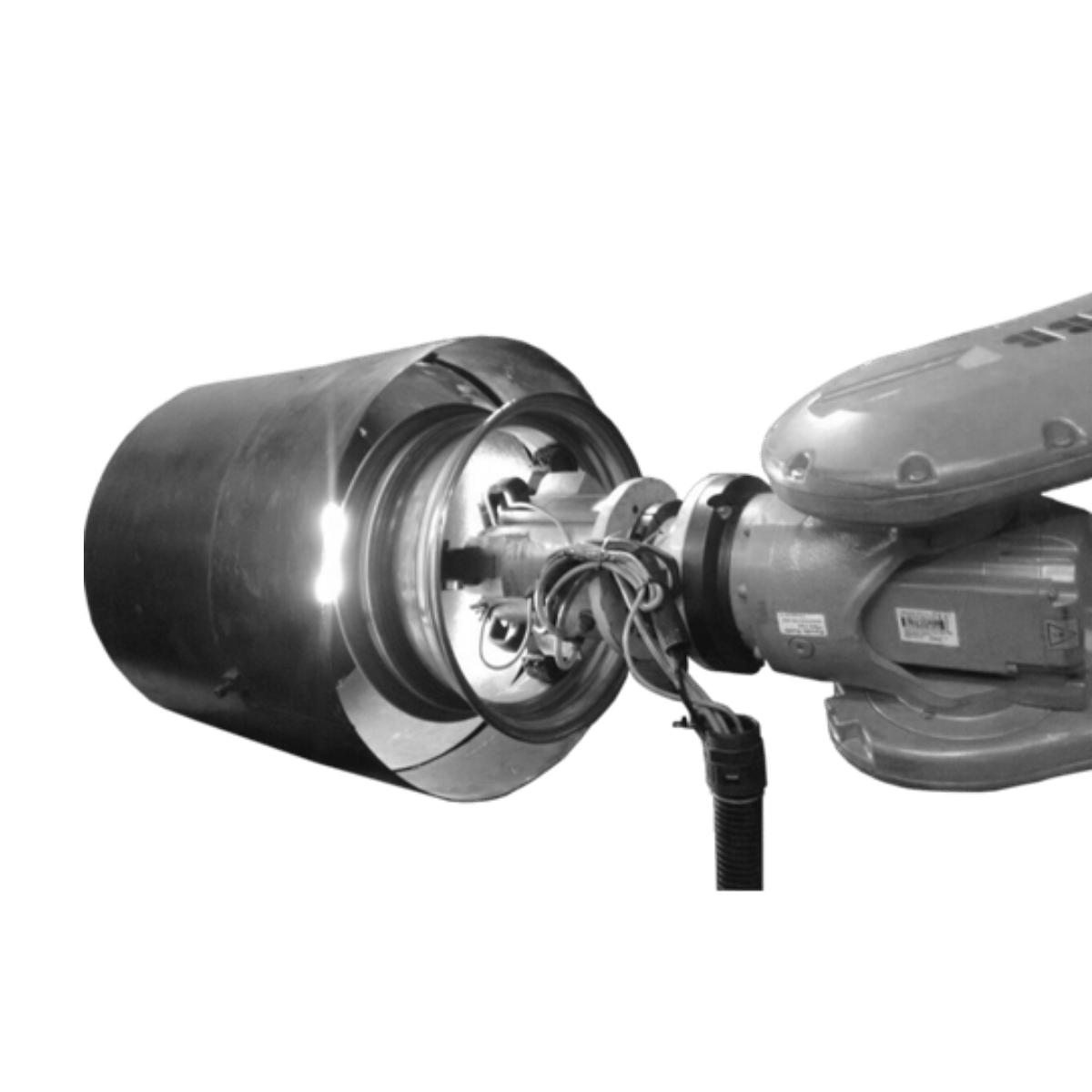

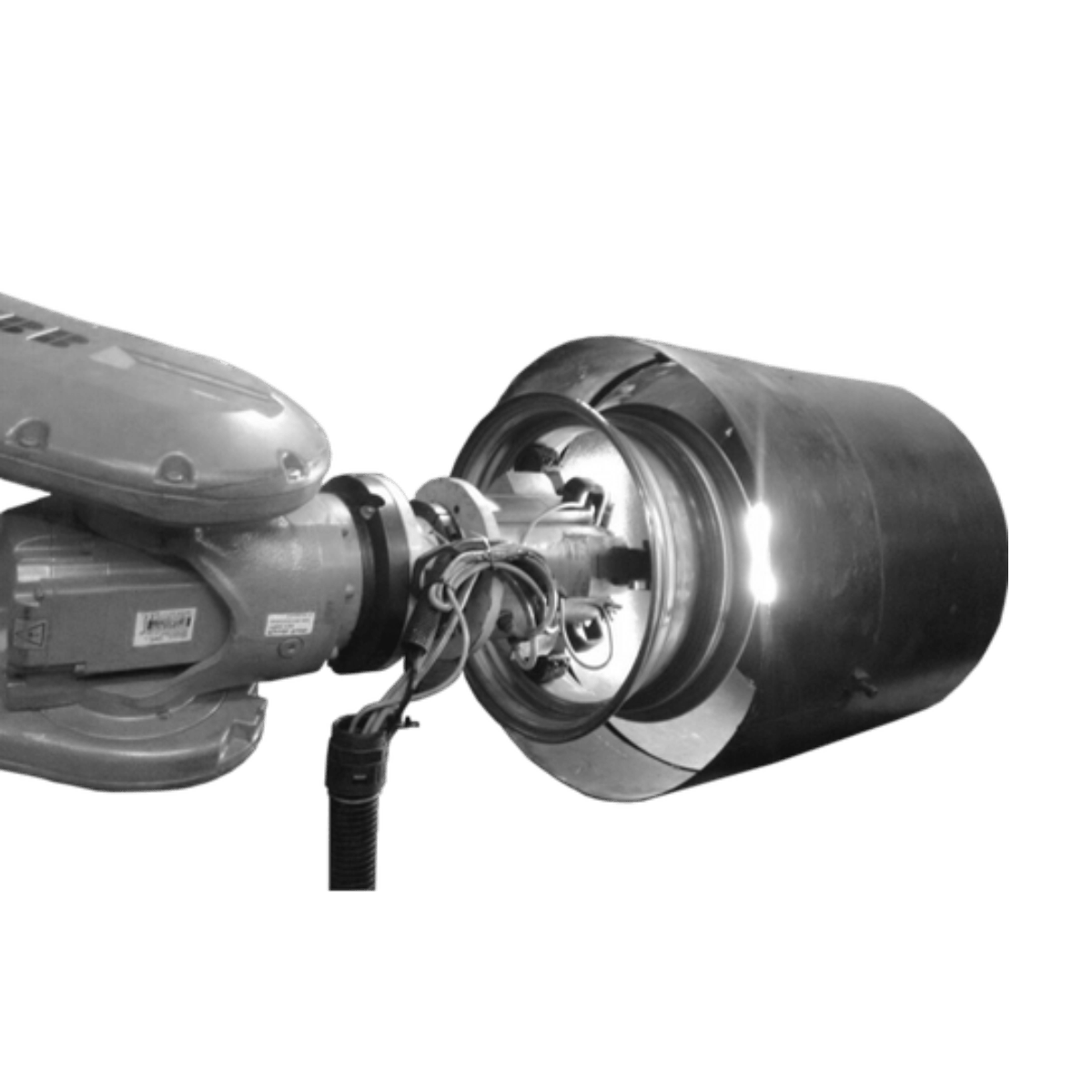

In partnership with ABB Robotics, Spookfish offers an automated solution which swiftly and accurately locates the weld bead on wheel rims, allowing the valve hole to be drilled in the correct position.

The system is compatible with a wide range of wheel sizes, and can increase productivity by up to 6 times.

Using robust pre-processing algorithm, Discus is capable of continuous 24 hours a day operation, and is even tolerant to significant environment and ambient changes. Trend charts and predictive analysis are also generated to inform the operators and increase fault tolerance.