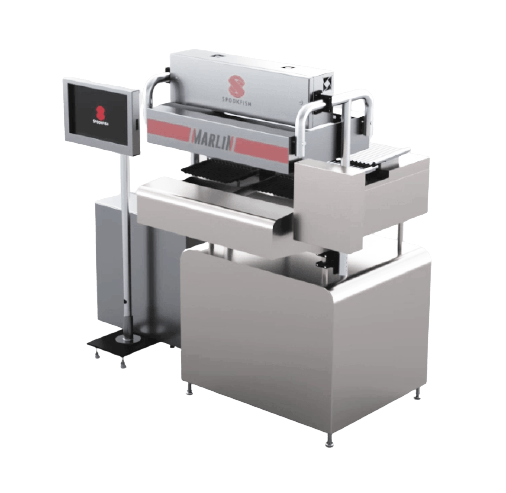

Marlin is an online tablet inspection system, retrofitted to a wide range of existing bottle filling lines with minimal alterations to the existing setup.

Most tablet and capsule production lines include some form of visual inspection prior to loading onto a counter (either manual or automatic). However, defective products and foreign objects can make their way onto the counter during handling/loading and although rare, the impact to the business if undetected is critical.

The high speed cameras and customized software is capable of accurately detecting inconsistencies in tablet colour, shape and size, removing defective products via a custom-built rejection mechanism. The system can be configured to reject individual products or bottles.

Marlin has been tested and approved for use in live production environments using a wide range of variants including transparent capsules.