MICROPS Xi

IN-PROCESS BLANK AND MINTED COIN INSPECTION

MICROPS Xi

IN-PROCESS BLANK AND MINTED COIN INSPECTION

MICROPS Xi

IN-PROCESS BLANK AND MINTED COIN INSPECTION

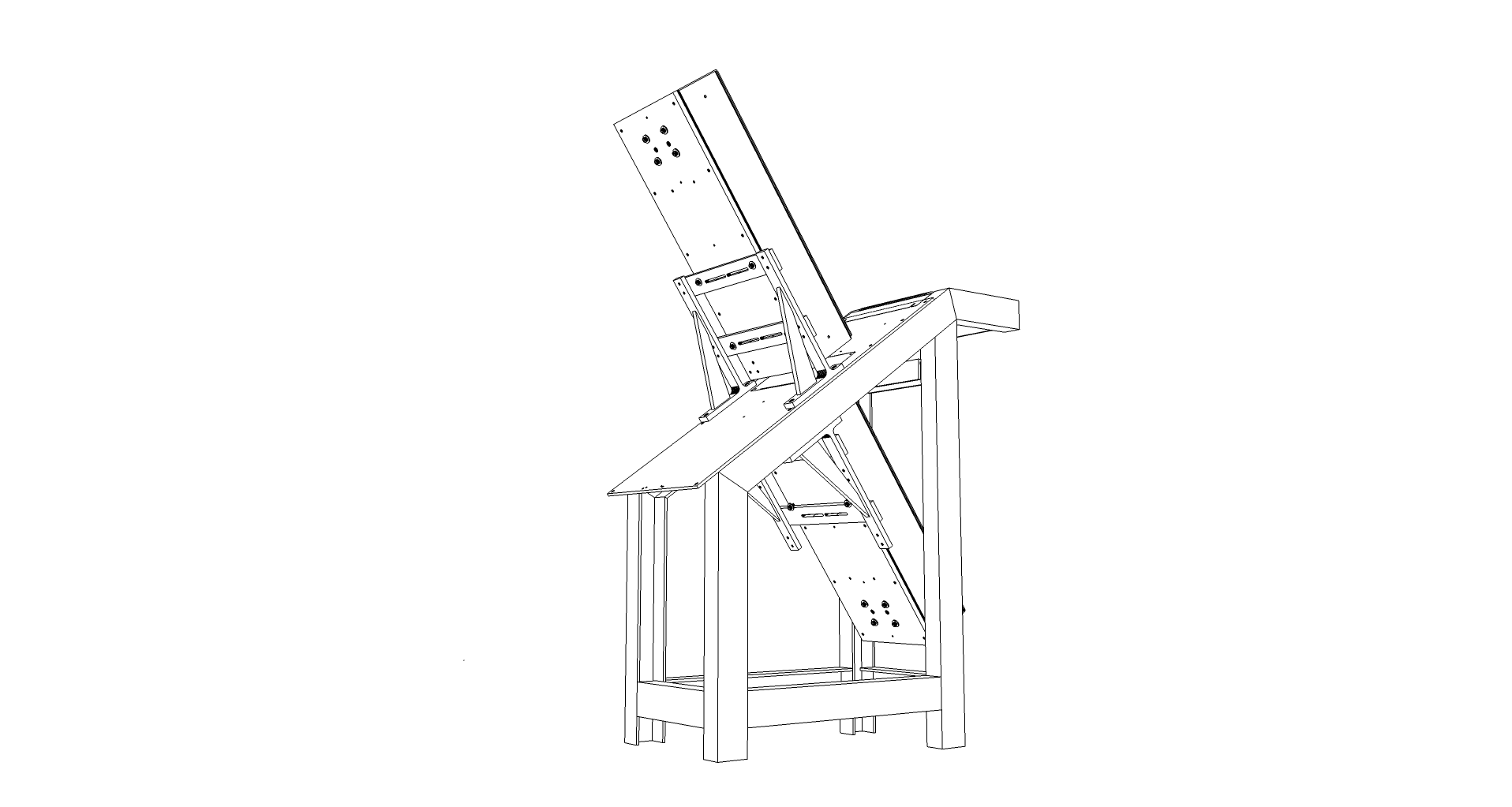

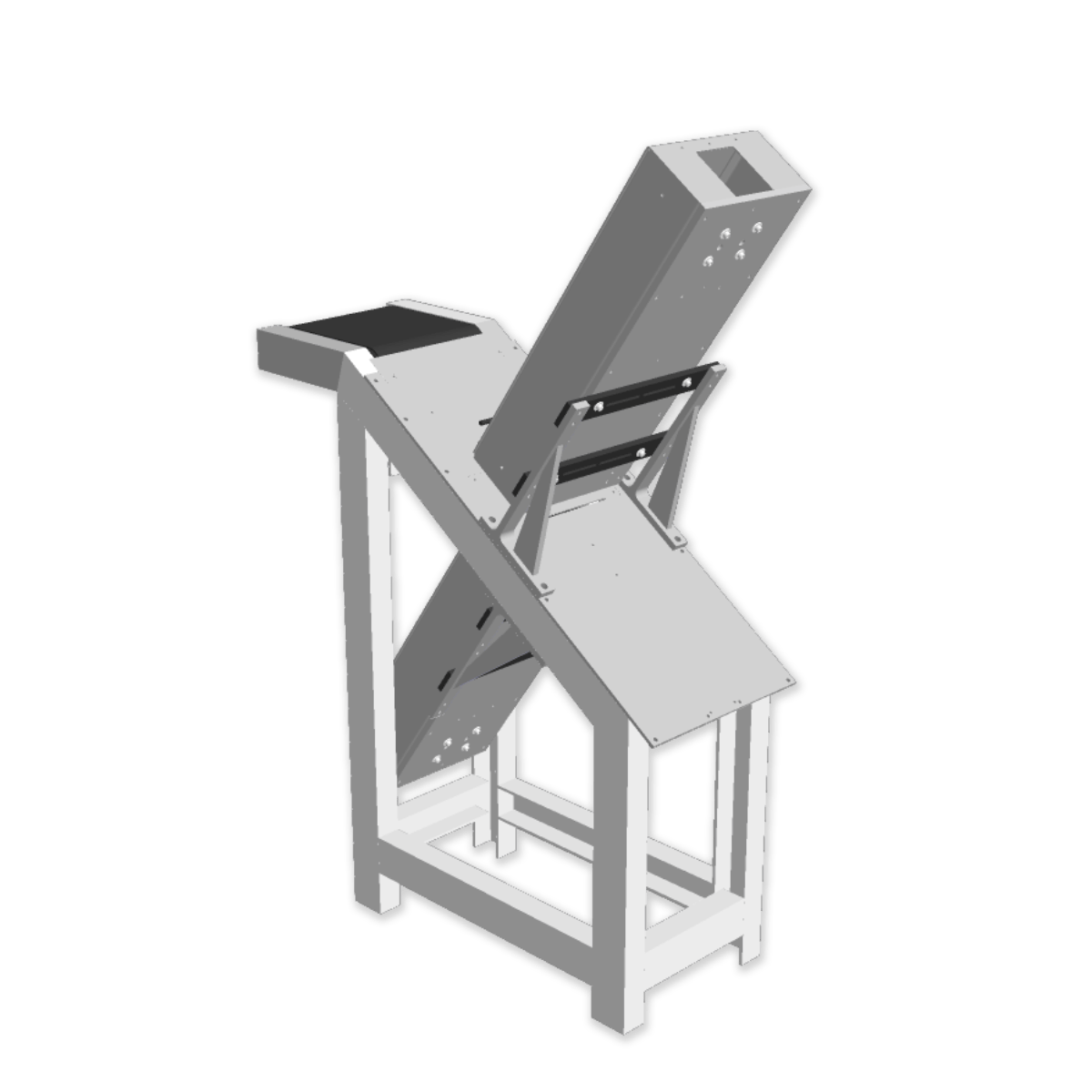

Microps Xi is an in-process coin inspection solution for retrofit to a coin press, scanning up to 1,500 coins per minute to an accuracy of up to 50 microns.

This lightweight system maintains a high level of precision without creating a bottleneck in production, making 100% inspection achievable at an affordable cost.

Concurrent inspection of both sides of the coin enables top and bottom mint alignment verification, in addition to the standard quality checks. The compact design not uses minimal floorspace, but also significantly reduces overall system system complexity and maintenance.

Microps, next generation coin inspection.

IN ACTION

- Compact design

- Mint alignment verification

- (top and bottom side)

- High speed and high precision

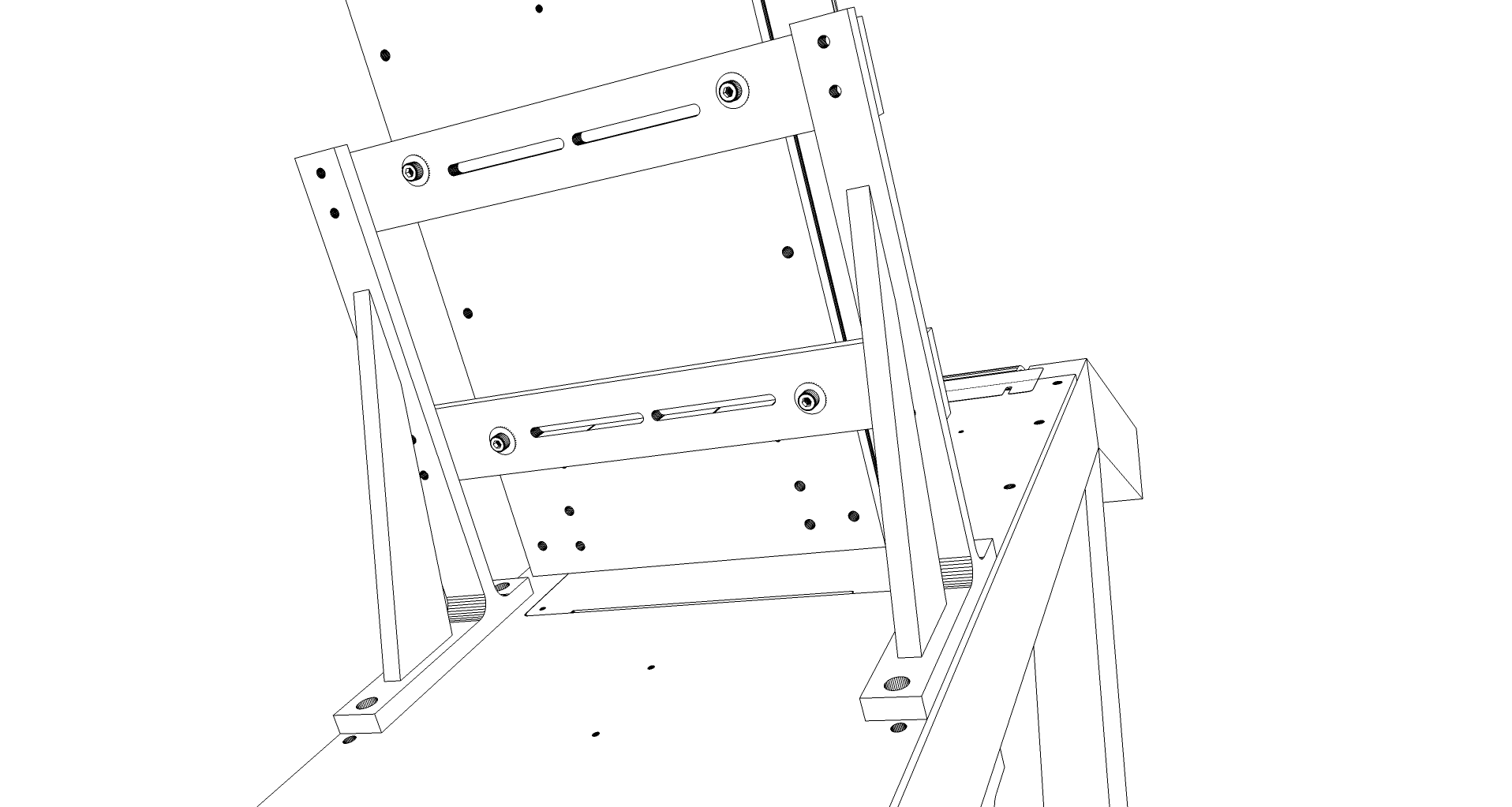

- Automated system calibration

- Pneumatic rejection system

- Self cleaning camera system

- Remote operation

- Real-time/Archived statistics and analysis

- 100% accuracy up to 50 microns

- Up to 1500 coins per minute

- Diameter (outer): 12mm -35mm

- Diameter (inner): 8mm - 30mm

- Campatible with all metals (Steel, nicket, copper,bimetallic, sliver, aluminium, etc.)

- Compatible with all coin types (circular, ring, bemtallic, scalloped, etc)

- 60 seconds calibration

Download the product brochure for more specifications

OTHER PRODUCTS

EXPLORE OUR PRODUCTS WITHIN THE SECTOR

-

Stand-alone blank and minted coin inspection

Product pageMICROPS X

-

Coin classification and sorting

Product pageMICROPS C